Preventative Maintenance

Preventative Mainten...

Preventative Maintenance

We offer multiple service plans to suit your needs.

Semi-annual, annual, and battery maintenance plans are available to keep your system running efficiently and without interruption.

Semi-Annual Preventative Maintenance Plan

Full Service

- Check for online status. Record any anomalies.

- Perform a complete visual inspection of UPS. Record any damage.

- Record system model.

- Record part number.

- Record serial numbers.

- Record any unit specific identifier number.

- Record all applicable display readings.

- Check alarm history. Record any irregular messages.

- Check fans for proper operation.

- Checks all lights and indicators for proper operation if applicable.

- Verify remote status panel operation if applicable.

- Review system performance to address any issues & schedule repairs.

- Provide an inspection report, with recommendations.

Annual Preventative Maintenance Plan

Full Service

Consists of Semi-Annual service, plus the following:

- Transfer UPS to Static (internal) Bypass. At site contacts approval.

- Transfer Load to Maintenance Bypass. (If applicable).

- Follow proper operating procedures

- Shutdown UPS to perform an internal inspection.

- Perform a complete visual inspection of all internal sub-assemblies, wiring harnesses, contactors, cables.

- Remove covers and check the following:

- AC/DC Capacitors for any irregularities.

- Record part numbers and date code.

- Check all fuses.

- Check all contacts to ensure secure connections.

- Verify connections show no sign of discoloration.

- Implement manufacturer field change notices, as possible.

- If possible measure and calibrate, as necessary.

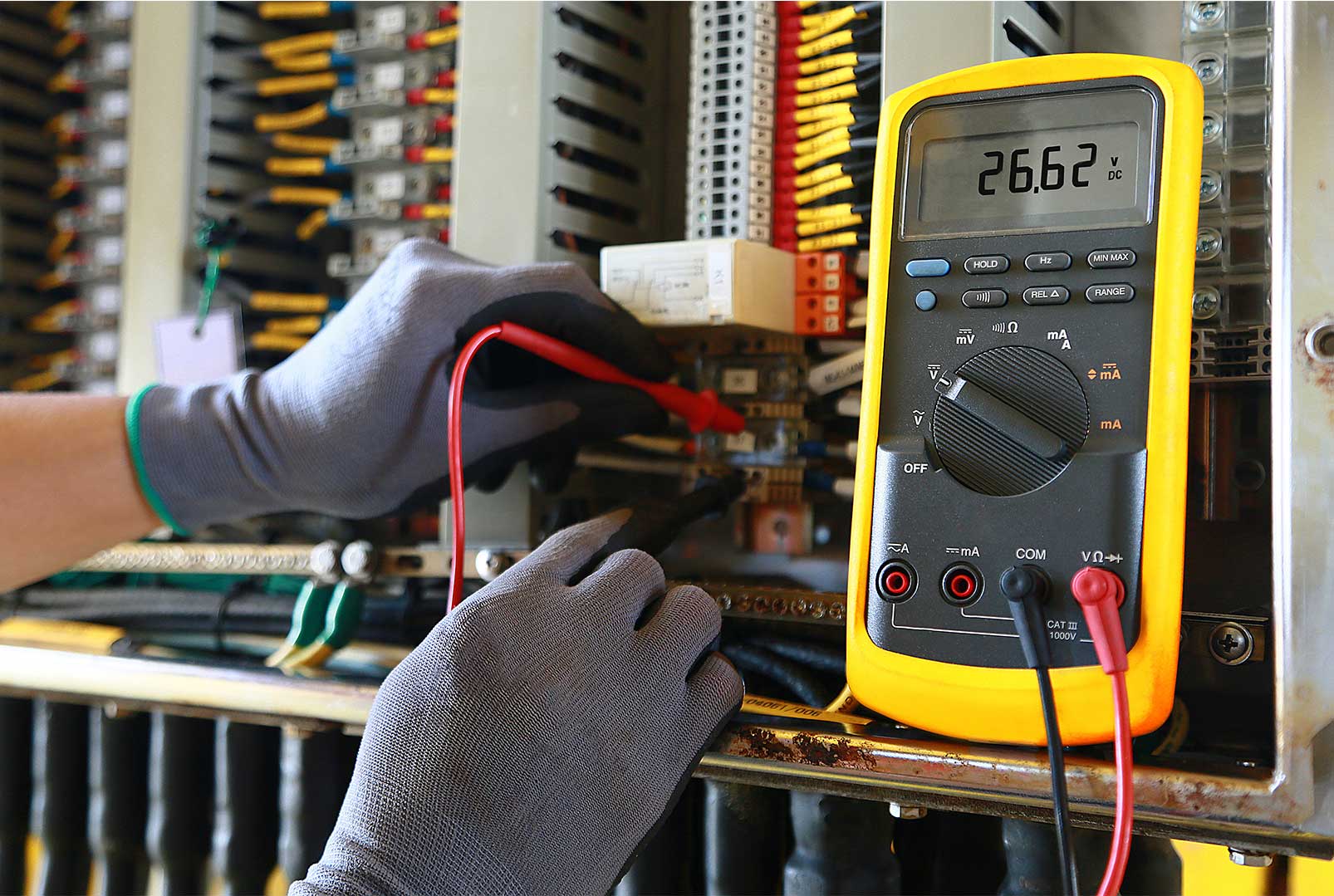

- Measure and record phase-to-phase input, output, bypass, and battery voltages and currents.

- Perform temperature checks on all breakers, connections, & associated controls.

- Record all high temperatures.

- Perform all necessary calibrations.

- Clean interior and exterior of units.

- Re-start UPS following proper operating procedures.

- Return to Static Bypass.

- Transfer Load to UPS Static Bypass.

- Transfer UPS Online.

- Perform functional system tests upon customer REQUEST.

- Check safety equipment and supplies for the current amount and location.

- Confirm proper warning/hazard labels.

- Place UPS online while operating in Maintenance Bypass mode to ensure UPS operates correctly.

Our Gold Maintenance Plan includes major and minor preventative maintenance services on both UPS & batteries.

One major UPS preventive maintenance • One minor UPS preventive maintenance • 7 x 24 emergency service • Parts replacement

Major preventative maintenance service includes:

- Coordination of services with appropriate site personnel

- Check and re-torque system terminal connections

- Clean oxidation from terminals as required

- Remove dirt, dust and debris from inside the system cabinets and/or racks

- Check and record charging voltages and currents of all battery components. Test individual battery with conductance meter

- Verify integrity and proper operation of all system components and sub-assemblies

- Perform a 5 minute discharge test on the battery components if approved by customer

- Full reporting of completed tests and system abnormalities

- Provide all battery test data recorded during system test

- Provide equipment test data recorded during the system testing

- Provide a written analysis of the operation of the equipment

- Detail any equipment defects that would cause the system not to perform to its full capabilities

Minor preventative maintenance service includes:

- Coordination of services with appropriate site personnel

- Remove dirt, dust and debris from inside the system cabinets

and/or racks. Check and record charging voltages and currents - Verify integrity and proper operation of all system components and sub-assemblies

- Perform any required calibrations

- Record all operating voltages currents and waveforms

- Full reporting of completed tests and system abnormalities

Our Remedial Maintenance Plan includes major and minor preventative maintenance services on both the UPS & batteries.

One major UPS preventive maintenance • One minor UPS preventive maintenance • 7 x 24 emergency service

Major preventative maintenance service includes:

- Coordination of services with appropriate site personnel

- Check and re-torque system terminal connections

- Clean oxidation from terminals as required

- Remove dirt, dust and debris from inside the system cabinets and/or racks

- Check and record charging voltages and currents of all battery components. Test individual battery with conductance meter

- Verify integrity and proper operation of all system components and sub-assemblies

- Perform a 5 minute discharge test on the battery components if approved by customer

- Full reporting of completed tests and system abnormalities

- Provide all battery test data recorded during system test

- Provide equipment test data recorded during the system testing

- Provide a written analysis of the operation of the equipment

- Detail any equipment defects that would cause the system not to perform to its full capabilities

Minor preventative maintenance service includes:

- Coordination of services with appropriate site personnel

- Remove dirt, dust and debris from inside the system cabinets

and/or racks. Check and record charging voltages and currents - Verify integrity and proper operation of all system components and sub-assemblies

- Perform any required calibrations

- Record all operating voltages currents and waveforms

- Full reporting of completed tests and system abnormalities

Battery Maintenance Service Plan

Full Service

- Perform visual inspection.

- Check jar and cover for signs of cracking or leakage.

- Record battery model number.

- Record date code.

- Record number of batteries in each string.

- Record number of strings.

- Perform temperature scan of each battery and record irregular readings.

- Measure and record overall system DC and AC voltage and current levels.

- Measure and record ambient room temperature.

- Measure and record VDC & VAC of each jar/cell.

- Perform conductance testing.

- Check for corrosion on terminal post and connector.

- Provide inspection report with recommendations

- Includes all steps above, plus…

- Inspect electrolyte levels and record for future action.

- Visually inspect jars, terminals, connectors, racks, and cabinets.

- Inspect proper operation of ventilation system.

- Check for unintentional battery grounds.

Site by DAY Vision